On Rana Plaza Anniversary, Cascale Members Recommit to Worker Safety

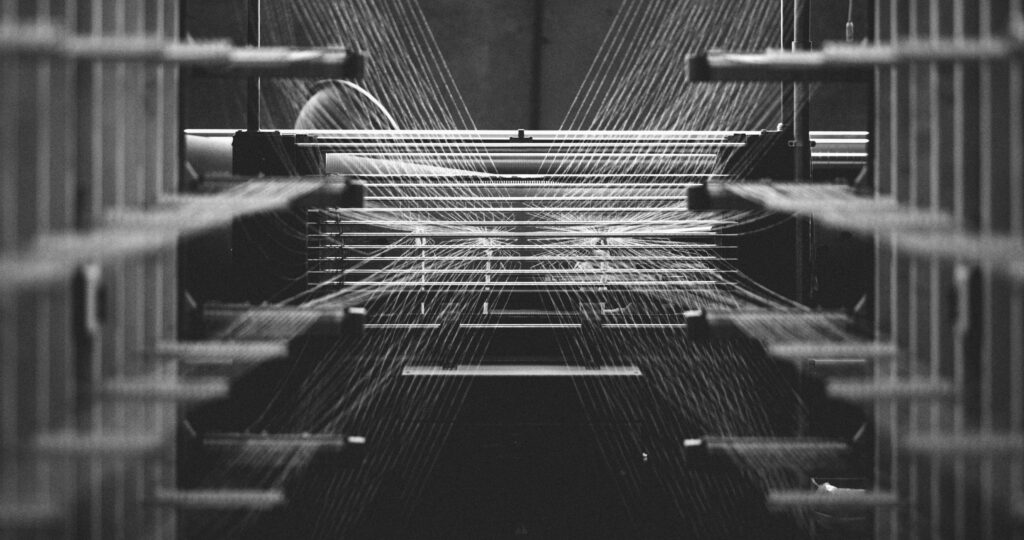

On April 24, 2013, the apparel and textile industry stood still.

News of the Rana Plaza factory collapse rippled through apparel supply chains and the devastation – 1,134 workers killed and several thousand injured – led to the reimagination of garment workers’ rights.

Read more about this date of remembrance.